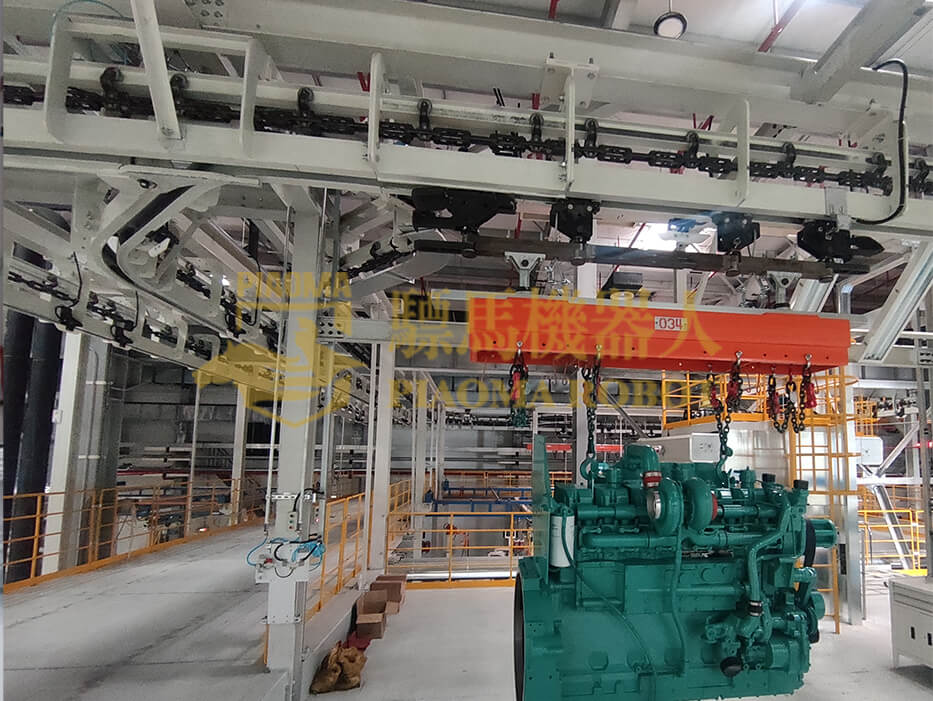

Piaoma Robot

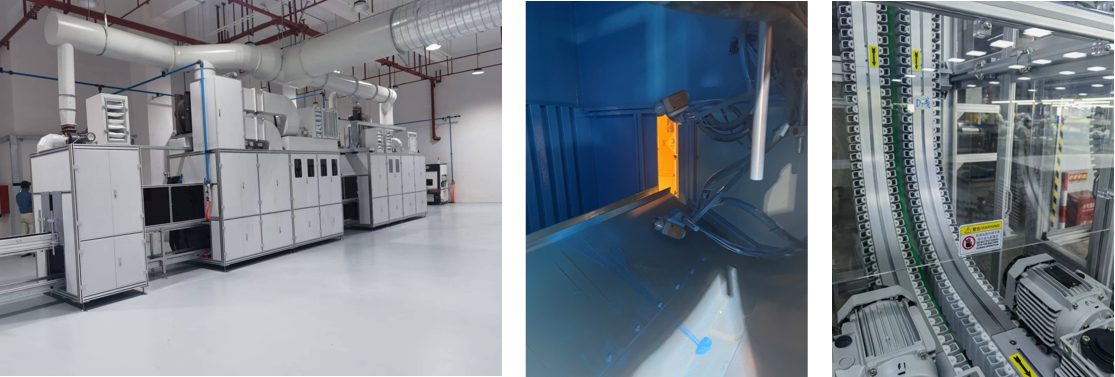

Cell UV spraying

1. The product performance has been significantly improved, with significant improvements in insulation, adhesion, shear strength, and other indicators;

2. During the production process, there will be no bubbles or wrinkles, and there will be fewer reworked products. The yield of a single product can reach 96%; 3. The production line has a high degree of flexibility, which can meet the production of different models of products and the rapid change of product types

2. During the production process, there will be no bubbles or wrinkles, and there will be fewer reworked products. The yield of a single product can reach 96%; 3. The production line has a high degree of flexibility, which can meet the production of different models of products and the rapid change of product types

Detail

Features of the production line:

The product performance has significantly improved, with significant improvements in insulation, adhesion, shear strength, and other indicators; 2. During the production process, there will be no bubbles or wrinkles, and there will be fewer reworked products. The yield of a single product can reach 96%; 3. The battery cell end is sprayed, and the offline process can be grouped without affecting the existing process; 4. The production line has a high degree of automation, and can be fully automated for loading and unloading, pre-treatment, UV spraying, online quality inspection, and defect repair; 5. Low energy consumption, low installed power, and small footprint; 6. The product can be launched multiple times with an extremely low scrap rate;

Advantages of Piao Ma:

1. Puma has over 30 years of experience in integrating spray painting and drying production lines, providing more optimized solutions and high-quality services; 2. Puma has been conducting research on replacing blue film with battery cells and improving the safety performance of battery cells for many years, with a large amount of technical accumulation and the implementation of pilot lines; 3. Through strategic cooperation with leading paint manufacturers and laser cleaning manufacturers in the industry, Puma can achieve rapid response of the entire line solution and provide one-stop services.

Intelligent manufacturing system service provider

Piaoma has over 30 years of professional experience in automation equipment and 18 years of background in automotive factory planning and construction. It can provide overall solutions and high-quality services for production lines